The successful export and long-term deployment of a swivel manual recliner chair depends heavily on the performance of its surface materials. For B2B buyers and wholesalers, upholstery is not merely aesthetic; it is a critical technical specification that dictates product lifespan and warranty claims. We must analyze fabrics and leather based on rigorous laboratory standards to verify Swivel manual recliner chair fabric abrasion resistance, stain repellency, and thermal comfort.

Home Furniture Oversized Electric Power Recliner Chairs with Massage Function

Abrasion resistance, the material's ability to withstand rubbing and friction, is the primary indicator of long-term durability. It must be quantified using global industry testing standards.

The required abrasion rating must be specified based on the intended application. Commercial environments (hotels, lobbies) demand significantly higher cycle counts than standard residential settings to manage continuous, high-frequency use of the swivel manual recliner chair.

| Application Category | Required Martindale Cycles (Minimum) | Required Wyzenbeek Double Rubs (Minimum) |

|---|---|---|

| Light Residential Use (Decorative) | 10,000 - 15,000 | 15,000 - 20,000 |

| Heavy Duty Residential (Daily Use) | 25,000 - 40,000 | 30,000 - 40,000 |

| Commercial/Public Use (High Frequency) | Over 50,000 | Over 50,000 |

Beyond wear, the ability of the upholstery to repel contaminants is vital for low-maintenance products. This is key to long-term client satisfaction and is measured via controlled chemical tests.

Natural leather, particularly full-grain or top-grain with a protective finish, offers exceptional durability and a natural resistance to pilling and aging. However, engineered performance fabrics often surpass leather in Stain and liquid repellency for swivel chairs due to specialized finishes. When choosing High durability leather for swivel recliners, thickness and finish type (aniline vs. pigmented) are the core technical variables.

User comfort is an often overlooked but critical technical specification, especially concerning heat and moisture management.

Comprehensive quality assurance requires adherence to multiple Upholstery material testing for recliner chairs protocols. These include ISO 12945 (Pilling), which assesses the tendency of fabrics to form fuzz balls, and ISO 105 B02 (Colorfastness to Light), which ensures the material's color will not fade noticeably under light exposure.

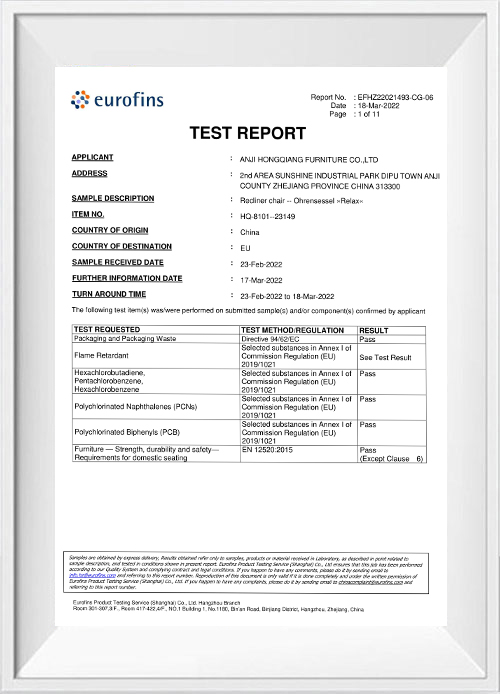

Anji Hongqiang Furniture Co., Ltd., established in 2012, specializes in exporting furniture supplies, including a popular line of recliner chairs and **swivel manual recliner chair** models. Our 10,000 square meter factory, located strategically near Shanghai and Ningbo ports, operates under strict management systems. We understand that success in the over 500 global markets we serve relies on precise technical specifications. We fully support customized design—from fabrics and sponges to structures and appearances—allowing our partners to select specific Swivel manual recliner chair fabric abrasion resistance levels and achieve optimal Breathability rating for recliner upholstery. We sincerely welcome partners to visit and cooperate on the basis of long-term mutual benefits, providing products optimized through rigorous Upholstery material testing for recliner chairs.

For a high-frequency commercial environment, the minimum recommended Martindale score should be over 50,000 cycles to ensure adequate Swivel manual recliner chair fabric abrasion resistance and durability.

Long-term seating comfort, particularly related to heat, is quantified by measuring the fabric's vapor permeability (moisture transmission) and thermal conductivity, which collectively contribute to the Breathability rating for recliner upholstery.

High durability leather typically refers to thick top-grain or corrected-grain leather treated with pigmented or protective finishes. These finishes significantly enhance resistance to abrasion, scratches, and stains compared to delicate aniline leather.

The anti-fouling and stain resistance properties are verified using standards such as AATCC 22 (Water Repellency) and AATCC 130 (Soil Release), which assess the material's resistance to liquid penetration and its Stain and liquid repellency for swivel chairs.

Two other key checks are Pilling Resistance (e.g., ISO 12945), which assesses fuzz formation, and Colorfastness to Light (ISO 105 B02), which assesses the material's resistance to fading over time.